Description

wire straightener and cutter - Streamline Your Wire Cutting Process

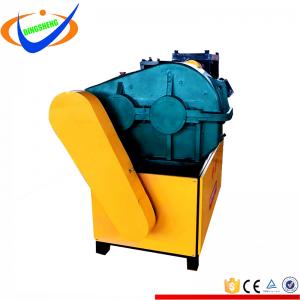

wire straightener and cutter introduction:

In today’s fast-paced industrial world, precision and efficiency are paramount. When it comes to wire processing, having reliable equipment to straighten and cut wires is essential. The wire straightener and cutter is a versatile machine that revolutionizes wire processing, offering speed, accuracy, and ease of use.

Wire straightener and cutter is a machine designed to remove the bends, twists, and unevenness from wires, ensuring they are perfectly straight and ready for use. Additionally, it cuts the wire to the desired length with precision, saving time and effort. This useful tool is widely used in various industries, including construction, manufacturing, automotive, and electronics.

| Model | DS 6-12 |

| Straight wire diameter | 6.0 - 12.0 mm |

| Work speed | 35 m/min |

| Cutting length |

Customized as your requirements |

| Motor power | 4.0 kw + 4.0 kw |

| Coil shelf | Customized as your coil wire weight and diameter |

| Error | Zero error with hydraulic cutting |

Automatic high speed wire straightening and cutting machine advantages:

- Adopt the totally enclosed type case, featured with high security.

- Adopt cartridge valve, featured with compact structure and convenient adjustment.

- The oil-way controlling part is hidden under the panel which can resist dust effectively.

- The feed inlet adopt rotary scuff sleeve, featured with simple structure and easy change.

- Part of the funnel structure was closed which is convenient for dust-cleaning.

- The structure of the cradle is more reasonable, as well as new appearance.

- The straightening motive power came from the large power motor which can ensure a long time stable operation.

- The installation of traction and straightening motive power adopt adjustable structure, which is easy to maintain.

wire straightener and cutter prove to be invaluable tools across various industries, offering improved efficiency, enhanced precision, and increased safety. By automating the wire processing tasks, these machines contribute to streamlined production processes and facilitate the creation of high-quality end products. When selecting a wire straightener and cutter, consider factors such as wire diameter and length range, speed and feed capability, automation features, and maintenance requirements. With the right machine in place, you can revolutionize your wire cutting process and stay ahead in today’s competitive market.

wire straightener and cutter