Description

Scrap Steel Bar Wire Rebar Straightening Machine

The scrap rebar straightening machine is one kind of construction equipment mainly manufactured for straightening and cutting various shapes of scrap rebar. Its main functions is to straightening, specified-length cutting, elongation and derusting to the curved steel, scrap steel and steel material head in accordance with the customers’ real needs. The scrap steel straightening machine is in small size and easy to move. Furthermore, it has a high working efficiency and a long operating life. This kind of scrap straightening machine will be your good choice.

Model

DSFG 6-14

DSFG 8-18

DSFG 12-18

DSFG 10-25

Voltage

380 V

380 V

380 V

380 V

Power

4.0 kw

7.5 kw

11.0 kw

15.0 kw

Rebar thickness

6-14 mm

8-18 mm

12-18 mm

10-25 mm

Speed

25 m/min

25 m/min

25 m/min

30 m/min

Weight

400 kg

650 kg

850 kg

900 kg

Dimension

1050*680*1280 mm

1140*720*1280 mm

1250*900*1280 mm

1450*960*1350 mm

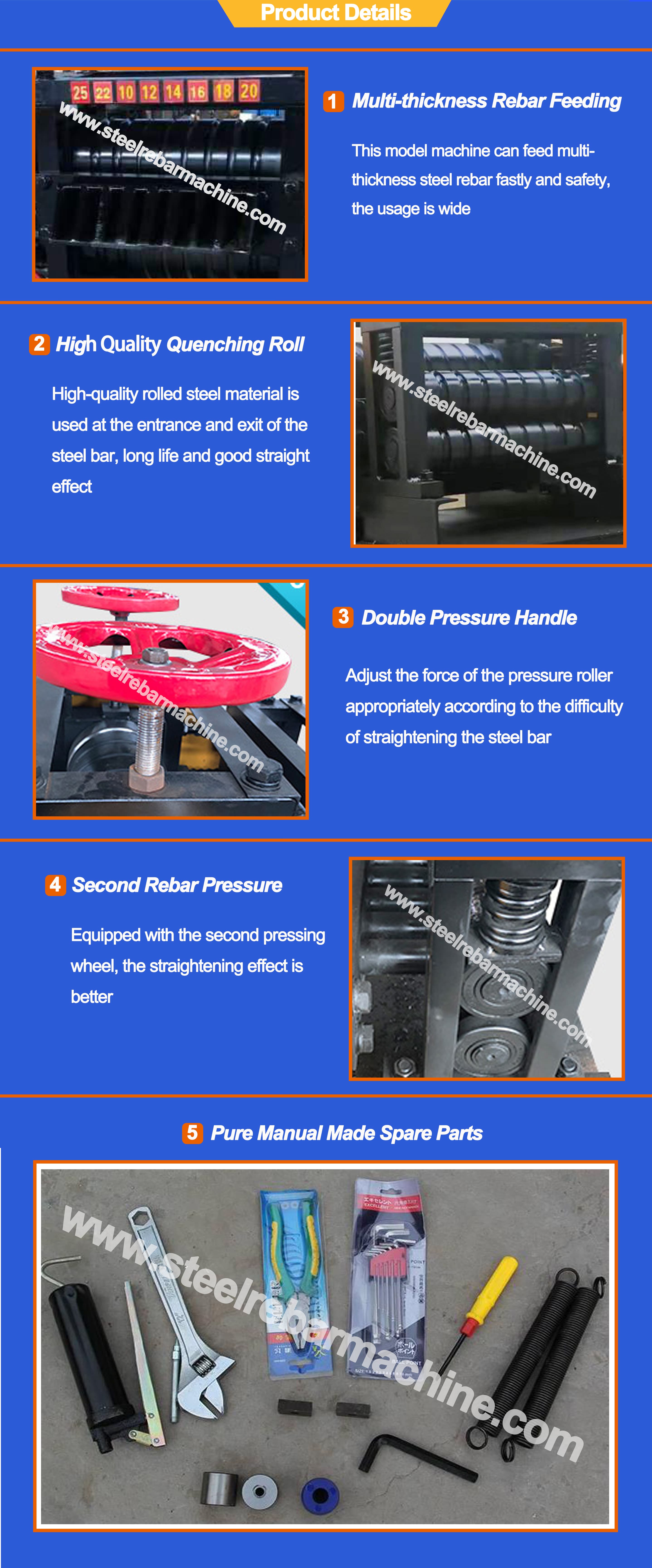

Features Of Scrap Steel Bar Wire Rebar Straightening Machine

1. Quick and accurate straightening with less scratches in steel surface.

2. Good straightness to improve the work efficiency.

3. Low failure rate with stable performance.

4. Save time and labor costs.

5. Fast, efficient and green.

6. Simple and safe to use.

Advantages Of Scrap Steel Bar Wire Rebar Straightening Machine

2. The straightening frame of the scrap rod straightening machine adopts five curve wheels to give the scrap bar good straightness.

3. The four heavy-duty wheels of the scrap machine can be used to move the machine easily. It saves time and large labor costs.

Why Is Scrap Steel Bar Wire Rebar Straightening Machine So Popular?

Used Rebar Straightening Machine,waste steel bar straightening machine,Scrap Steel Bar Wire Straightener